Maximizing Ignition: Projected vs Non-Projected Spark Plugs

The spark plug is arguably one of the most critical components in any internal combustion engine. It functions as the source of ignition by generating the spark necessary to ignite the air-fuel mixture in the combustion chamber. This, in turn, keeps your engine running smoothly and efficiently.

The projection of the spark plug is a primary determinant of how the spark is delivered, which impacts combustion efficiency. The term spark plug projection refers to the extension or protrusion of the spark plug’s center electrode beyond the firing tip into the combustion chamber.

The level of projection can influence how effectively the spark plug initiates the ignition process by impacting factors such as flame propagation, combustion efficiency, and heat dissipation. Ideally, different engines and applications are designed to benefit from varying levels of spark plug projection.

Spark Plug Anatomy

The basic components of spark plugs are often similar across the board, but the specific design details and variations can be quite intricate. As such, the effectiveness and compatibility of spark plugs can vary depending on the specific details of their construction. That said, here’s a breakdown of the key components of a typical spark plug;

Shell – The shell is the outer casing of the spark plug, typically crafted from metal. Its primary function is to house and protect the internal components of the spark plug.

Threads – Threads refer to the screw-like portion of the spark plug that facilitates its secure attachment to the engine’s cylinder head. These threads play a crucial role in ensuring a tight and secure fit while preventing any leakage of combustion gases.

Gasket – A gasket is a mechanical seal between the spark plug and the engine’s cylinder head. The gasket prevents combustion gases from escaping the combustion chamber, thereby ensuring that the combustion process remains contained and efficient within the engine.

Hexagon – The hexagon is a six-sided nut or socket located at the top of the spark plug’s shell. Its purpose is to provide a convenient means for installation and removal using a corresponding hex wrench or socket tool.

Insulator – The insulator is composed of ceramic, which helps insulate the center electrode from the outer shell. Ideally, a projected insulator spark plug is crucial in preventing electrical current from flowing through undesired paths. This, in turn, ensures that the spark is directed only between the center electrode and the ground electrode.

Center Electrode – The center electrode is a metal rod extending from the center of the insulator into the combustion chamber of the engine. It acts as the conductor of electrical current, which plays a key role in producing the spark that ignites the air-fuel mixture during combustion.

Ground Electrode – The ground electrode is a metal piece located near the tip of the center electrode, often bent at a specified angle. Its primary function is to provide a surface for the spark to jump from the center electrode and initiate the combustion process.

Gap – The gap refers to the distance between the center electrode and the ground electrode. Proper gap size is essential for achieving optimal combustion efficiency and overall engine performance.

Terminal – The terminal is the metal connector situated at the top of the spark plug. It serves as the point where the ignition system delivers electrical current to the center electrode.

Projected vs Non-Projected Spark Plugs

Spark plug projection refers to the extension of the spark plug’s center electrode beyond the firing tip into the combustion chamber. The extension is designed to control the way the spark is delivered and how it interacts with the air-fuel mixture during ignition.

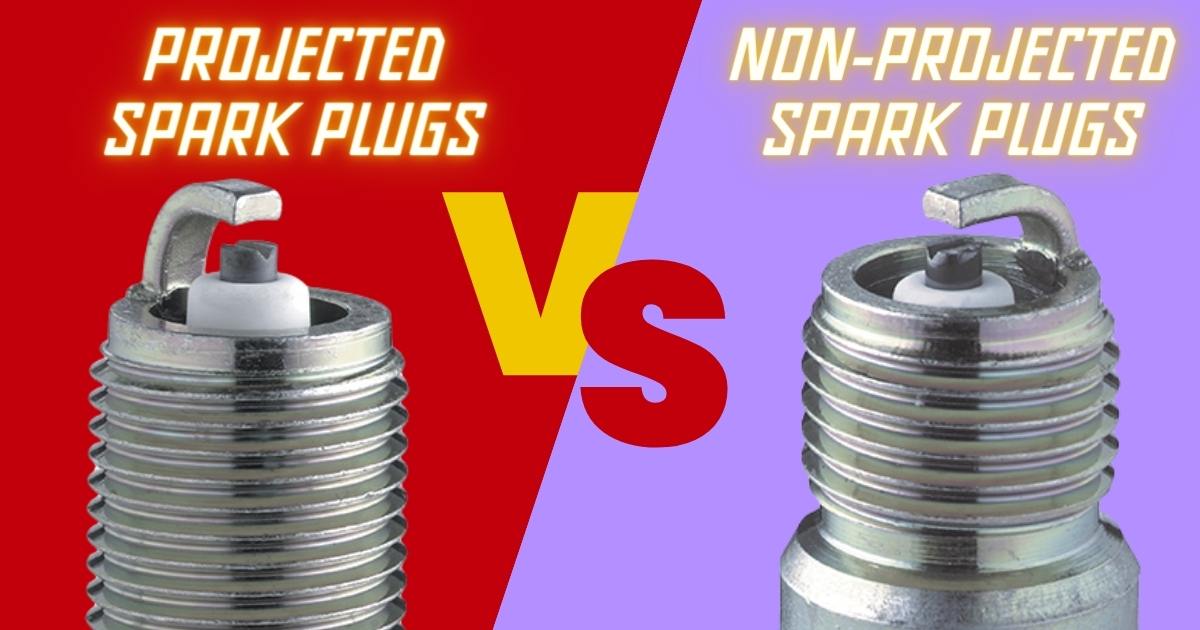

The projection of a spark plug is determined by measuring the distance from the end of the metal shell to the tip of the center electrode. This measurement serves as a crucial parameter in understanding the spark plug’s design, particularly how far the center electrode extends into the combustion chamber, as shown below;

Projected Spark Plugs

A projected spark plug is a design characterized by the extension of its spark plug’s center electrode beyond the firing tip and into the combustion chamber. This design helps to position the spark closer to the center of the combustion chamber, resulting in enhanced ignition efficiency and more uniform flame propagation. Projected spark plugs are often used in high-performance and racing applications that require precise ignition timing.

Advantages of Projected Spark Plugs

Improved Ignition – The extended center electrode promotes a more centralized spark, leading to better and more reliable ignition. This is particularly advantageous in high-performance engines.

Even Flame Spread – The projection into the combustion chamber helps create a spark in the middle, facilitating a more even flame spread during combustion. This contributes to a smoother and more efficient combustion process.

Enhanced Performance – Projected spark plugs are often preferred in racing and high-performance applications that demand ignition timing and consistent combustion for optimal engine performance.

Reduced Fouling – The projected design can help reduce the risk of spark plug fouling. This can be attributed to the positioning of the spark away from the insulator tip, which helps minimize the accumulation of deposits.

Limitations

Requires Tuning – Some engines may require specific tuning to capitalize fully on the advantages of projected spark plugs. The extra tuning can add complexity and may require professional expertise.

Compatibility Issues – Not all engines or vehicles are designed to accommodate projected spark plugs. As such, you may want to check the manufacturer’s recommendations and specifications to ensure compatibility.

Non-Projected Spark Plugs

A non-projected spark plug is a type of spark plug where the center electrode is contained within the body of the spark plug. In this design, the firing tip is either flush with or slightly recessed from the end of the spark plug.

The spark occurs closer to the center or at the firing tip, but is not centrally located within the combustion chamber. Non-projected spark plugs are commonly used in standard or everyday driving applications and are often found in stock or non-high-performance engines.

Advantages

Cost-Effectiveness – Non-projected spark plugs are generally more cost-effective than their projected counterparts. This makes them a preferred choice for standard or everyday driving applications.

Versatility – These spark plugs are often versatile and can perform well in a wide range of driving conditions.

Simplicity – The design of non-projected spark plugs is simpler, which contributes to easier installation and maintenance.

Wider Availability – Non-projected spark plugs are commonly used in many standard engines, and replacement parts are widely available.

Disadvantages

Impact on Ignition – As we have mentioned, the spark produced by a non-projected spark plug is not centralized within the combustion chamber. This can lead to slightly lower ignitability compared to projected spark plugs.

Flame Spread – The flame spread during combustion may not be as even as with projected spark plugs, which impacts combustion efficiency to a certain extent.

Fouling Risk – The design of non-projected spark plugs might be more susceptible to fouling since the spark occurs closer to the firing tip.

Spark Plugs Projected vs Non-Projected- Which One Should You Go For?

A well-designed spark plug ensures that it delivers a consistently powerful spark, which helps maximize the engine’s power output and smooth operation. That said, the choice between projected and non-projected spark plugs depends on several considerations, such as engine specifications, operating conditions, and performance requirements. Let’s go through these factors briefly;

Engine Specifications

Different engines may have specific requirements regarding spark plug design, heat range, and electrode configuration. For instance, engines with high compression ratios or modified combustion chamber designs may benefit from projected spark plugs, which provide enhanced ignition efficiency.

On the other hand, engines designed for standard driving conditions may find non-projected spark plugs to be a reliable option. As such, you may want to check the manufacturer’s recommendations to ensure compatibility and optimal performance.

Ignition Efficiency

The design of the spark plug plays a crucial role in determining how the air-fuel mixture is ignited within the combustion chamber. Projected spark plugs provide higher ignitability, making them optimal for high-performance engines. On the flip side, non-projected spark plugs, have a slightly lower ignition efficiency, making them suitable for standard driving conditions.

Operating Conditions

The operating conditions under which the engine is used are also a key determinant when choosing between a projected or non-projected spark plug. For instance, high-performance or racing environments require precise and rapid ignition. Projected spark plugs often outshine their non-projected counterparts with heightened ignitability and combustion stability in these demanding conditions.

In contrast, non-projected spark plugs offer a reliable and cost-effective solution for everyday driving scenarios. The spark plugs don’t require precise ignition, but they deliver satisfactory combustion stability, making them well-suited for routine commuting and typical driving situations.

Performance Requirements

Engines built for high-speed or racing often need a lot of power and precise combustion. In these situations, projected spark plugs are the go-to choice. Their unique design helps with quick and accurate ignition, which makes the engine work better. This means more power and a responsive engine.

For regular driving and standard engines that focus on reliability and saving fuel, non-projected spark plugs are often a good fit. While they still make sure the engine starts reliably and runs smoothly, non-projected spark plugs do not give the extra performance boost that projected spark plugs provide.

Maintenance Considerations

Projected spark plugs require more precise adjustments and maintenance due to their extended center electrode. This is particularly relevant in high-performance or racing applications. Depending on the engine and usage, projected spark plugs might need more frequent replacements, which can impact long-term maintenance costs.

On the other hand, non-projected spark plugs generally have a simpler design, making them easier to maintain. In addition, their straightforward construction reduces the need for frequent adjustments. Non-projected spark plugs also tend to have longer service intervals, plus you do not need replacement as often.

Conclusion

Maximizing ignition efficiency requires a thoughtful balance between spark plug selection and the unique characteristics of the engine. Ideally, the choice between projected and non-projected spark plugs should align with the engine’s specifications, operating conditions, and performance demands. That said, always refer to the manufacturer’s recommendations and consider the performance requirements of your engine when choosing the optimal spark plug.